Harris Rubin Studio had a pod table made from interlocking sheet metal in a convex shape that they wanted to adapt into a tulip table style concave shape, and they came to me to do the 3D manufacturable model.

This required an iterative process between the artist and myself, the manufacturing designer. First, I created a 2D print to capture some basic dimensions, number of horizontals, etc.

The biggest initial challenge was determining the shape of the curve. It was quickly determined that an elliptical shape was desirable over a true arc. To visualize the possible elliptical curves, I sent this short clip to the artist:

The artist then paused the screenshot at the closest desired curve.

From there, some further back and forth tweaking was required:

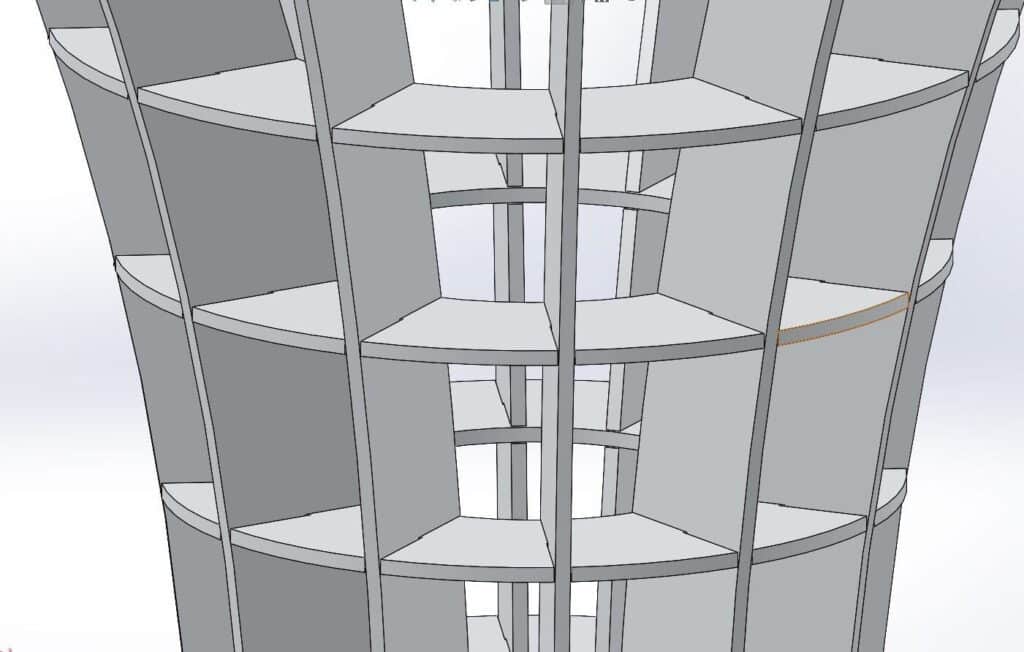

Once that was settled in, the artist wanted to experiment with number of verticals and visualize how that would affect the amount of light that would be let through in the open central column.

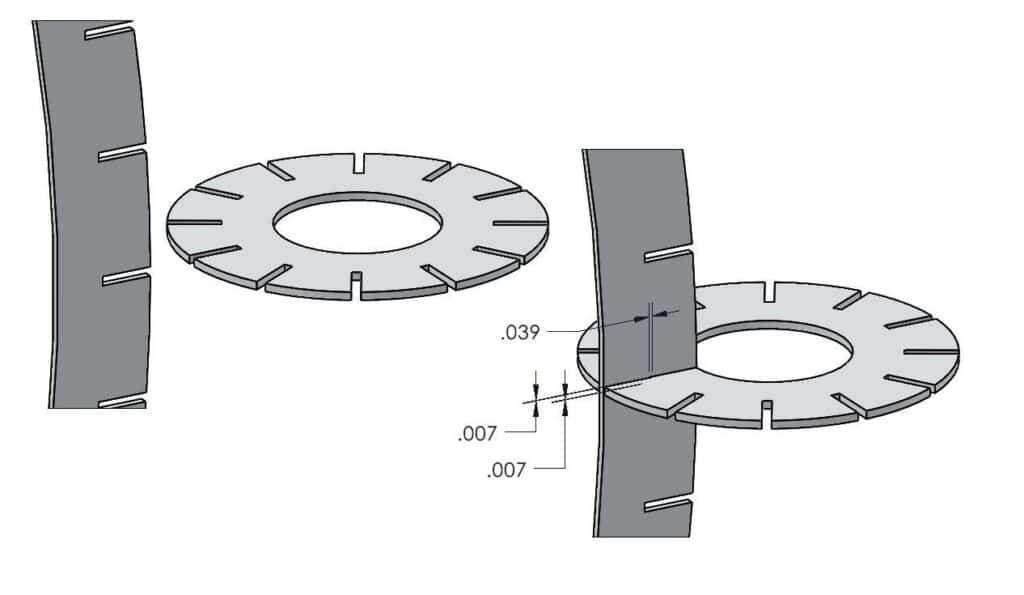

This model appears to be finished, but crucial design-for-manufacturing details were still missing, namely the proper tabs, slots and clearances so that the piece would be self-fixturing and easy to assemble prior to welding.

And finally, the completed model: